Lamborghini Gallardo

Superleggera LP 570-4

Specifications

- Scale: 1:4

- Length: 990mm / 39"

- Width: 425mm / 16.7"

- Height: 225mm / 8.9"

- Wheelbase: 580mm / 22.8"

- Total parts: 3,316

- Materials: 5mm foam core board

- 1000gsm cardboard

- 210gsm card stock

- 250gsm foil board

- 285gsm silver metallic card

- 250micron clear plastic

- Various other craft materials

Description

Built by Lamborghini from 2003 to 2013, the Gallardo was the manufacturer's best selling model, with a total of 14,022 built. Introduced in 2010, the LP 570-4 Superleggera was a lighter, more powerful special edition of the Gallardo. It featured a 5.2 litre V10 engine, with 570 PS (419 kW; 562 hp) at 8,000 rpm which provided performance of 0-100 km/h (62 mph) in 3.2 seconds, and a 329 km/h (204 mph) top speed.

The SuperCard Gallardo was painstakingly crafted piece by piece from scratch (3,316 parts in total) over a period of several years, in evenings and weekends. It is a detailed, quarter scale replica made from a range of craft boards and materials. The main structural parts are cut from sheets of either 5mm foam core board, or thick 1000gsm card board. The shiny black outer body panels are cut from sheets of 250gsm foil board. Other details are cut from 210gsm black card or 285gsm silver metallic card stock.

Features

- Removable bumpers

- Opening doors

- Opening front trunk lid

- Sub-frame and chassis detail

- Full engine and transmission

- Suspension and brake detail

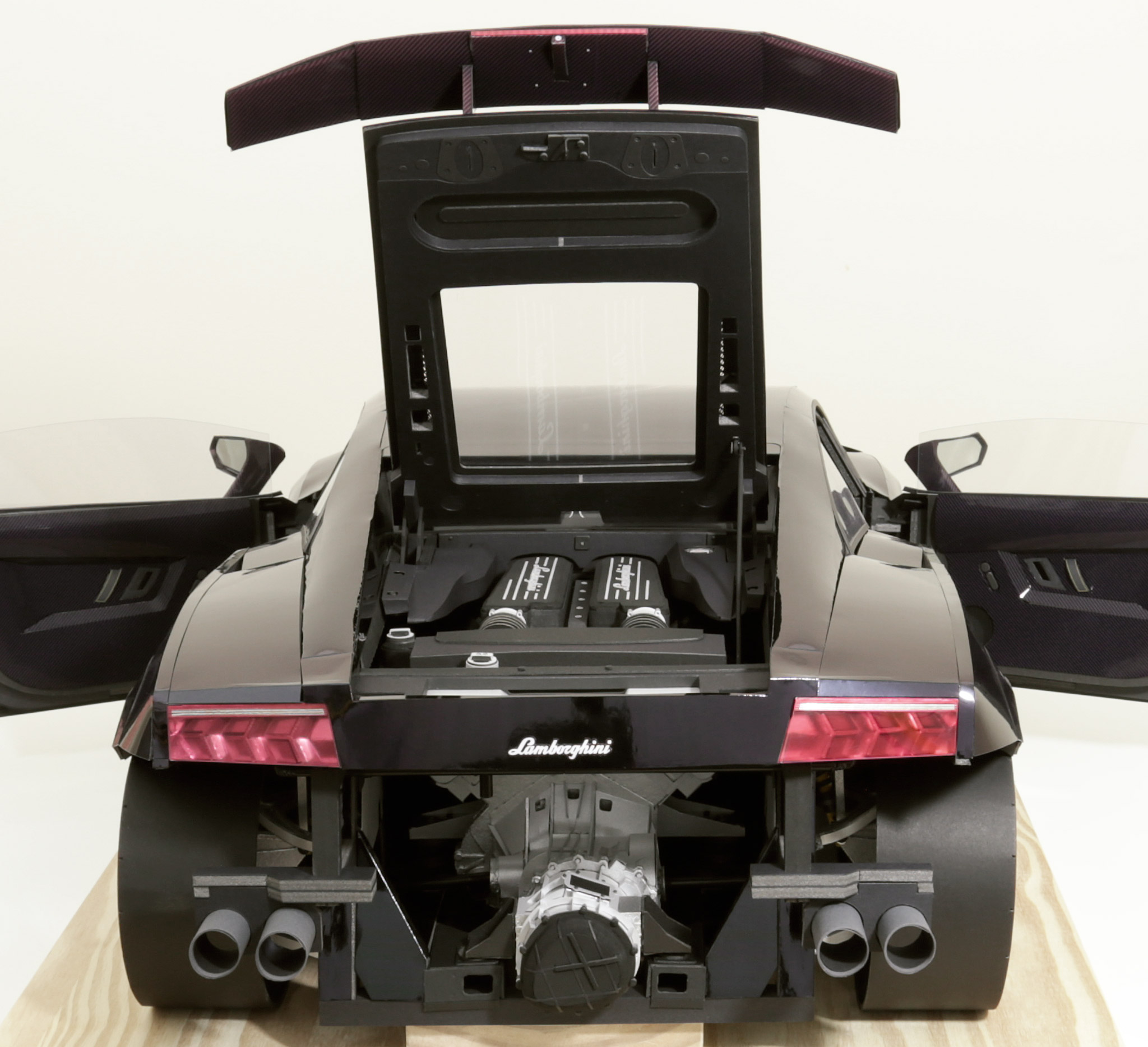

- ‣ Rear three quarter view of the finished Gallardo without the rear bumper fitted, and all the doors, engine cover, and front trunk lid open.

- ‣ Another image of the finished Gallardo, this time with the bumpers removed. The Gallardo took several years of work in my spare time to complete. The finished build is made up of 3,316 individual parts, all created from scratch (and most cut by hand). I learned a lot of new skills, overcome plenty of hurdles, and I'm super happy with the end result.

- ‣ Rear three quarter view of the finished Gallardo.

- ‣ Side view of the finished Gallardo.

- ‣ Rear three quarter view of the finished Gallardo with the doors, engine cover, and front trunk lid open.

- ‣ Rear three quarter view of the finished Gallardo.

- ‣ Front three quarter view of the finished Gallardo with all the doors, engine cover, and front trunk lid open.

- ‣ Rear three quarter view of the finished Gallardo without the rear bumper fitted, and all the doors, engine cover, and front trunk lid open.

- ‣ Rear three quarter view of the finished Gallardo without the rear bumper fitted, and all the doors, engine cover, and front trunk lid open. There were many more details that I could have added, but I was keen to wrap up the build by this point.

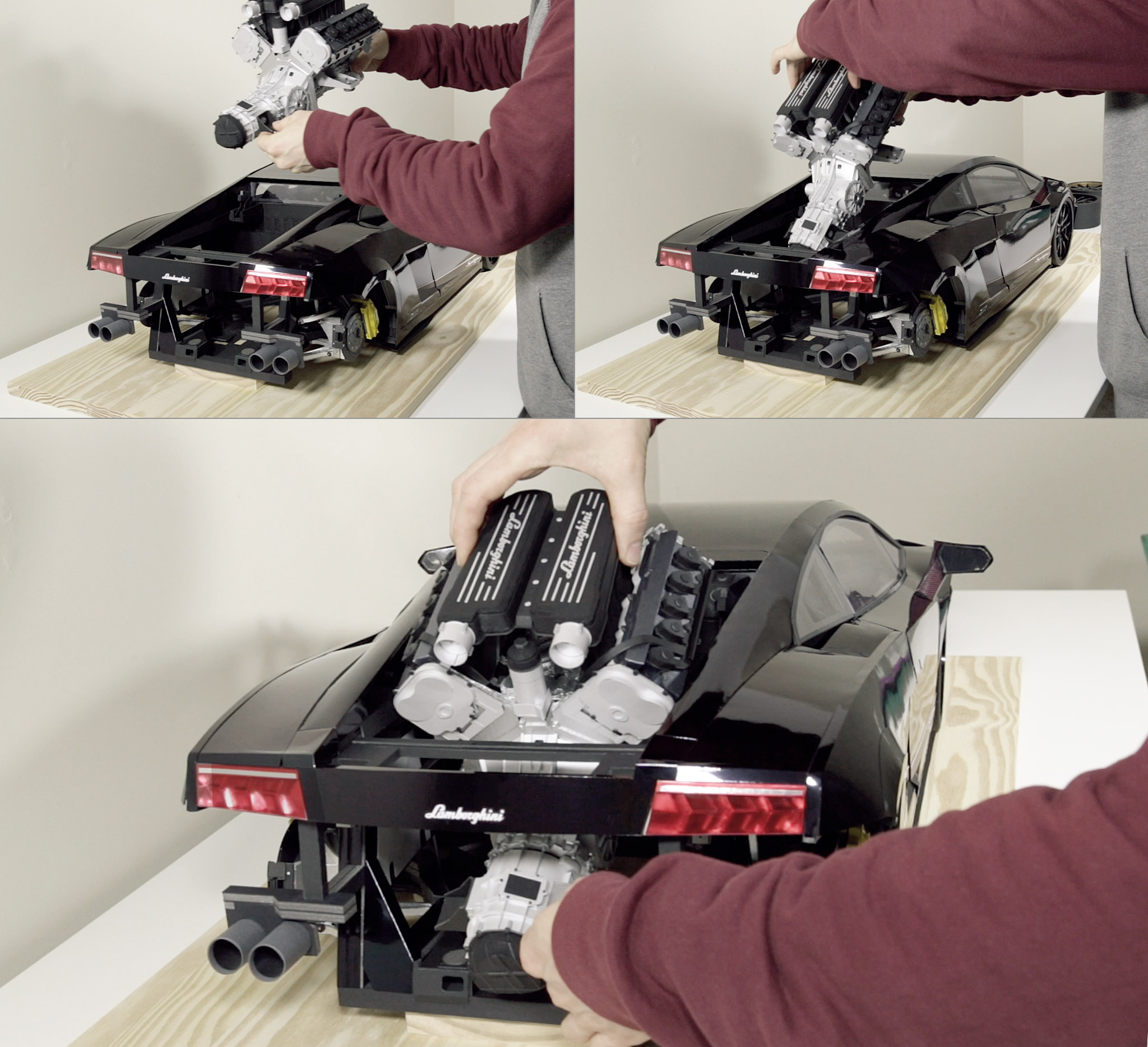

- ‣ A close up showing the engine and transmission fitted to the car. The engine bay is complete. I would have loved to build a complete exhaust system, and possibly build a twin-turbo set-up, but it was time to call this build 'done'.

- ‣ The Gallardo's rear-end, with the engine cover closed.

- ‣ The Gallardo's rear-end, with the engine cover open.

- ‣ Intake plenums and pipes seen looking down through the engine cover– just like on a real Gallardo. The clear window is hand-cut from clear plastic sheet called 'acetate'.

- ‣ Close up showing the engine and transmission fitted to the car. The engine bay is complete too, with the air box; intake pipes; power steering reservoir; and various aesthetic-covers fitted.

- ‣ With the rear bumper removed, you can see the engine and transmission in place. The fit is spot on– looks just like the real thing.

- ‣ The two rear wheelhouses (also known as fender liners). These sit up inside the rear wheel arches. Materials are 5mm foam core board; 1000gsm cardboard; 285gsm silver metallic card stock; and 210gsm black card stock.

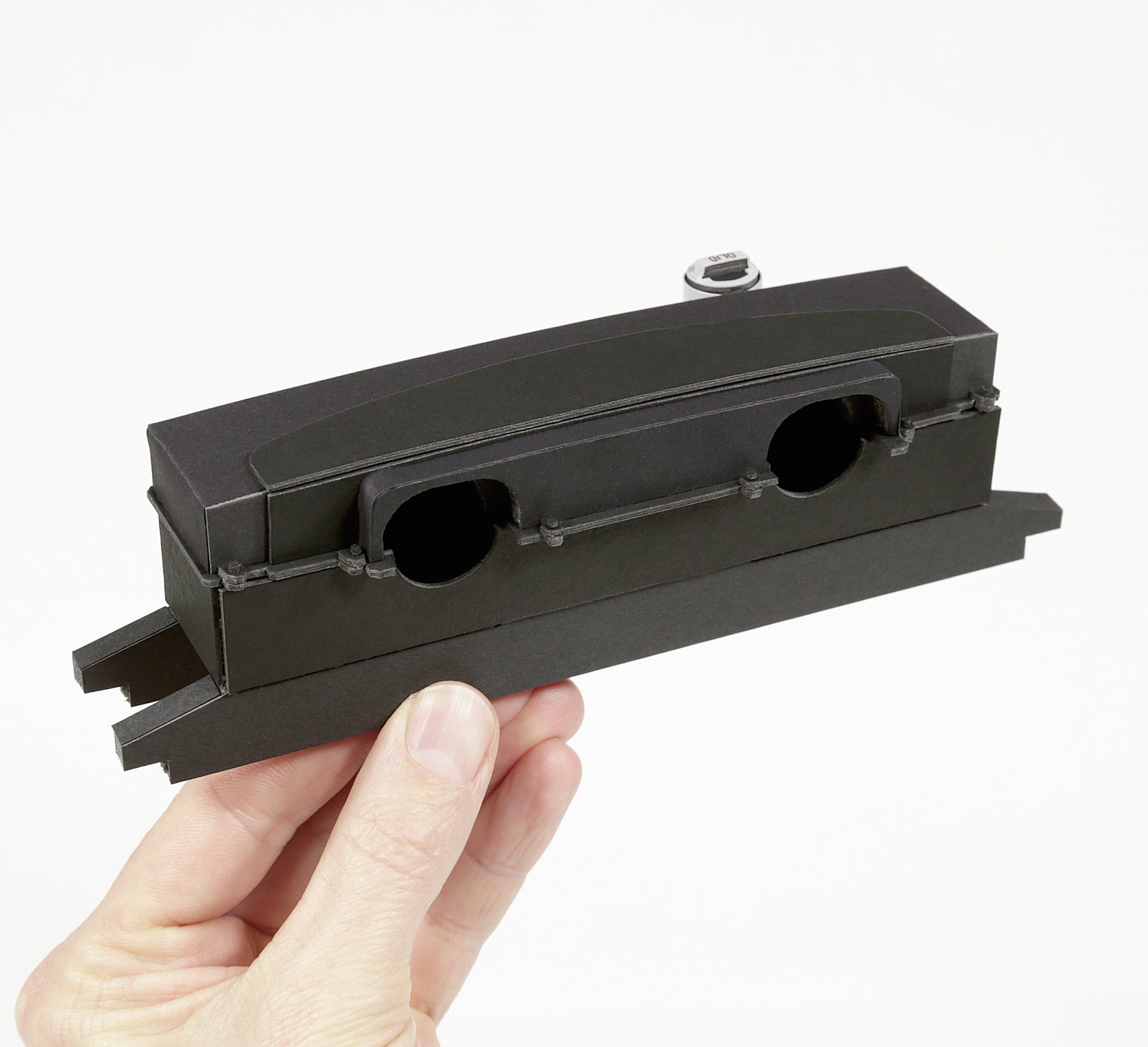

- ‣ Front-side of the air box. The two large holes are where the air-intake pipes enter the air box. Materials are 5mm foam core board; 1000gsm cardboard; 285gsm silver metallic card stock; and 210gsm black card stock.

- ‣ Rear-side of the air box. The assembly includes the 'olio' (oil) filler cap and pipe.

- ‣ A pair of engine bay aesthetic covers– incorporating the water filler cap for the cooling system (top right).

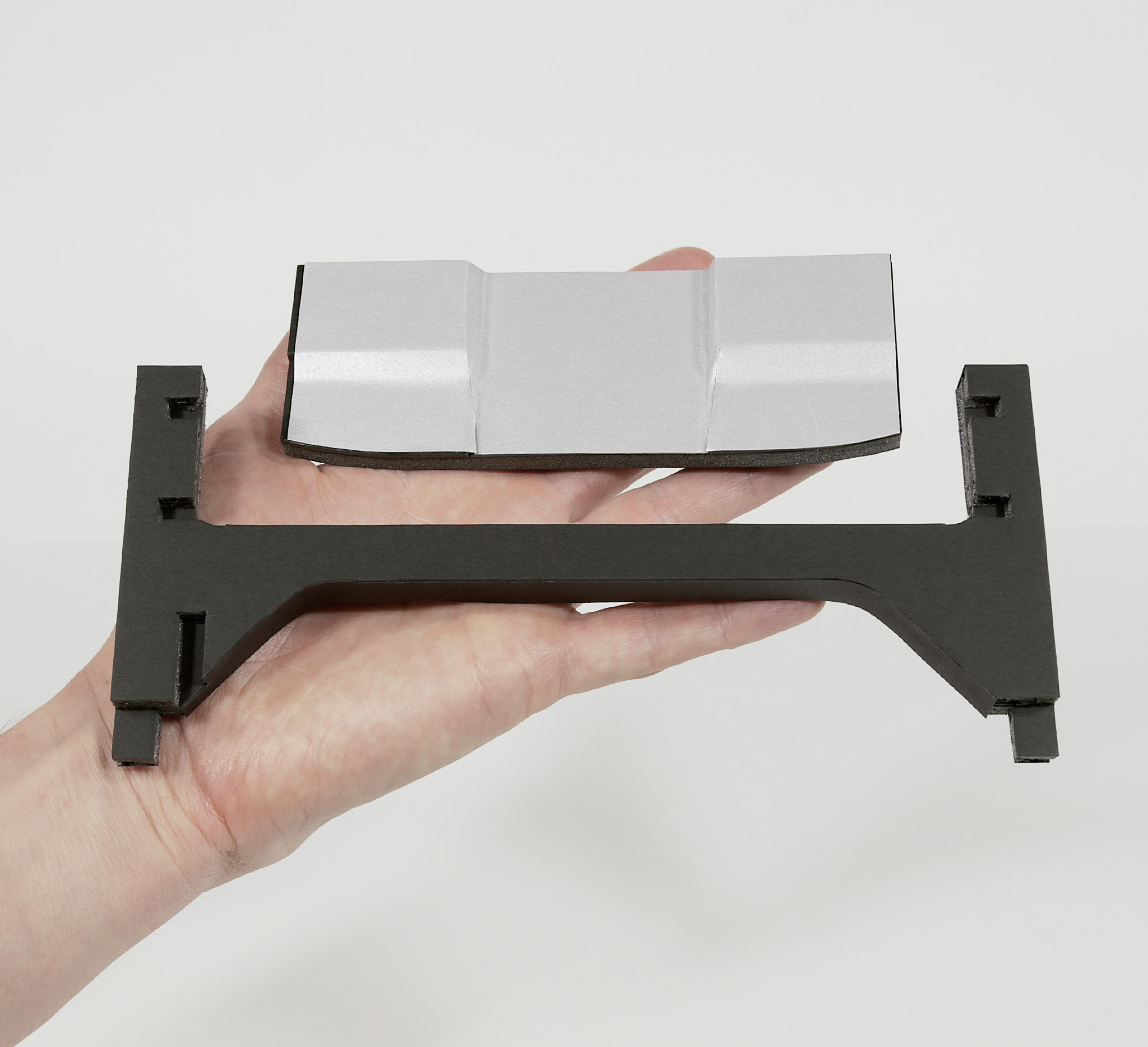

- ‣ Engine bay heat shielding (top) and the cross member which supports the air box (bottom). Materials are 5mm foam core board; 1000gsm cardboard; 285gsm silver metallic card stock; and 210gsm black card stock.

- ‣ Engine bay firewall panel/cover; intake piping; and power-steering reservoir.

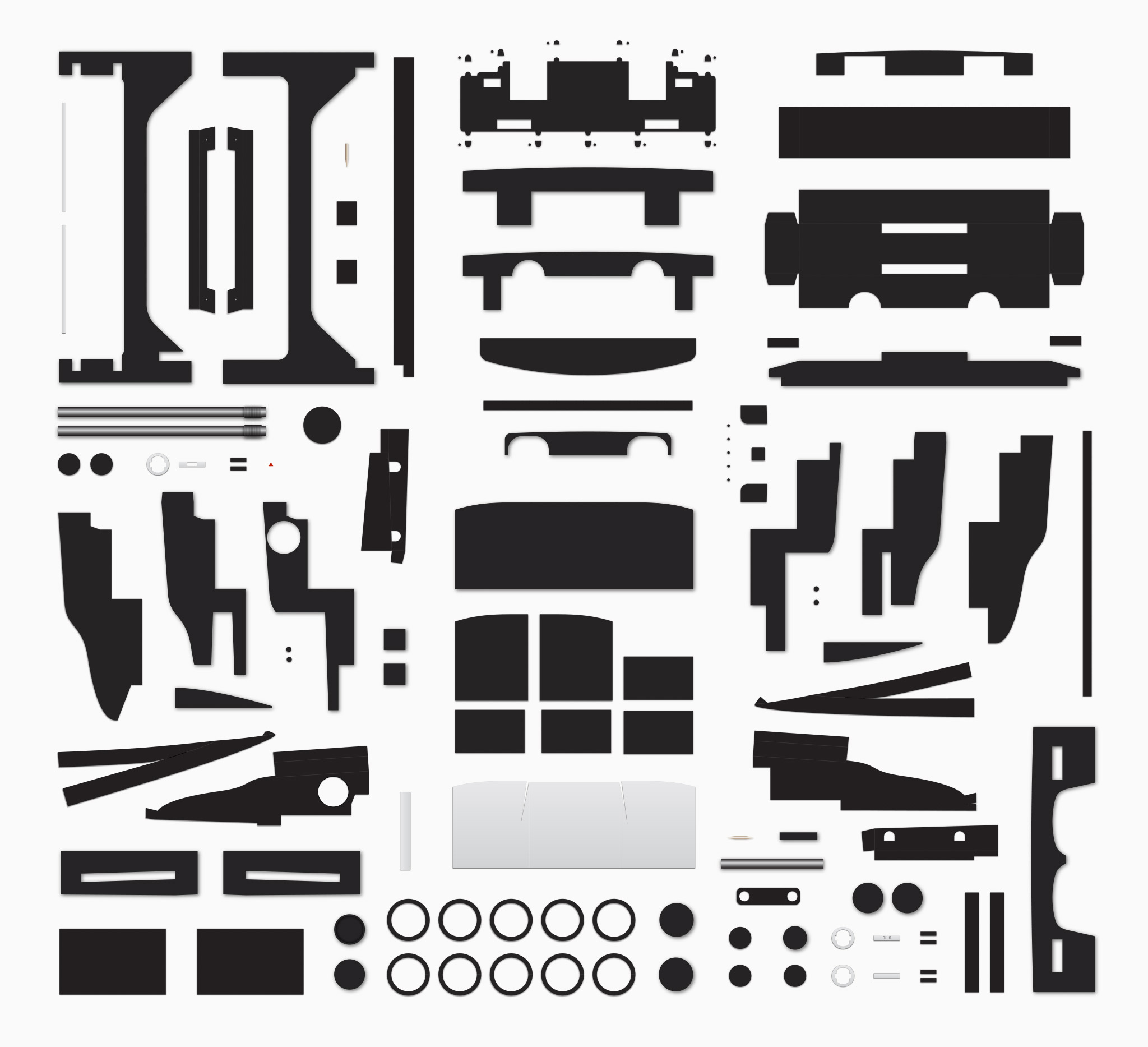

- ‣ Parts for finishing off various engine bay components, such as the air box; intake pipes; and heat shielding; and aesthetic covers. All designed from scratch and cut by hand.

- ‣ Fitting the engine and transmission. Everything fit and lined up pretty well. Only a few tweaks were needed to the height of the engine-mount bushes.